Whilst Tesla may have kicked off the Electric Vehicle (EV) revolution, today every major automaker in the industry is involved and are announcing the addition of more and more EV’s to their ranges on what feels like a weekly basis. In addition to the car industry’s established heavy-hitters, new EV specialist manufacturers are also entering the market – brands such as Byton, Lordstown and Rivian.

Whilst EV’s generate zero air pollution whilst being driven, depending on energy source today’s EV’s are often actually just pushing pollution ‘upstream’. This will eventually be resolved as the source of energy to power these cars moves from fossil fuel to alternatives such as solar power, wind turbines or even nuclear or hydroelectric. However this is achieved, the electrification trend which is currently shaping the future of mobility is here to stay, with bans on the sale of new Internal Combustion Engined (ICE) cars being phased in globally.

Electric vehicles and the impact on the automotive supply chain

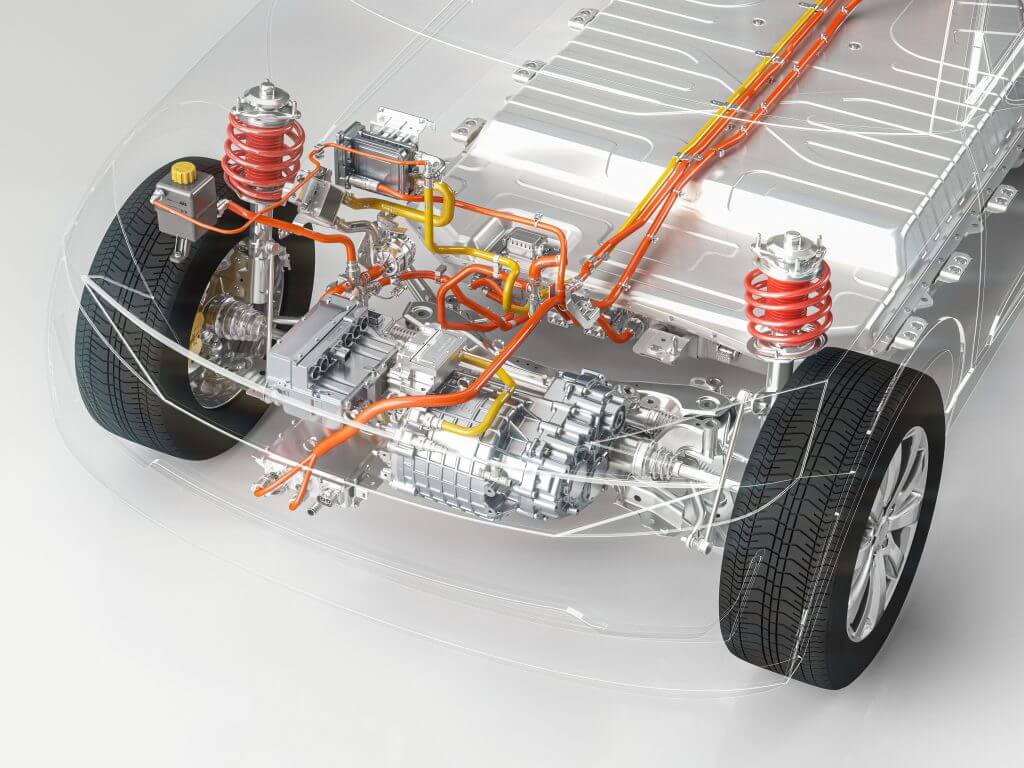

The rise in popularity of Electric Vehicles represents a significant disruption to large parts of the supply chain as lots of the major systems found on traditional ICE vehicles are simply not required with EV’s. In pure mechanical terms, EV’s are far simpler with single digit moving part motors, single speed transmissions, no fuel systems, no exhaust and no turbo or superchargers.

As OEMs continue to seek to future-proof their supply chains it is critical for suppliers to react and adapt, and automotive fastener suppliers are no exception. Automotive fasteners will play a major role both in terms of the new and specific applications surrounding electrification, and also in terms of the unique technical requirements.

New and exciting challenges for the Fastener sector

“Electric Vehicle technology places new and exciting challenges on our automotive fasteners sector,” explains AFL’s Managing Director, Scott Simpson. “Not only are there a surprisingly large number of fasteners required in the manufacture of EV’s, the technical requirements can be very different and more demanding than ICE applications.”

Specifying the right automotive fasteners for the Electric Vehicle Battery (EVB) alone is a key consideration, the battery needing to be as lightweight as possible to optimise performance and reduce energy consumption. It also needs to be both water and airtight, whilst remaining fully serviceable. Additionally, some of the connected components need to be conductive, while some require isolating qualities for safety reasons. Fastener cleanliness is also critical as any contamination present within the electric powertrain can lead to short-circuiting.

New challenges are also created as manufacturers move away from using standard steel in motor housings to different materials like aluminium and plastics, which require fastener solutions to handle different temperature and tolerance demands.

Helping to drive affordability and reduce emissions further

The broader role for fastener suppliers within the EV market lies in less obvious areas. Firstly, cost. Battery packs are currently incredibly expensive and affordability is one of the key factors affecting accessibility and adoption amongst the end user. To ultimately deliver affordable EV’s, manufacturers need to offset this expense and are increasingly looking to make savings across their entire manufacturing process. The right fastener partner can support this by offering solutions which deliver much improved manufacturing efficiencies.

Off vehicle emissions are another key focus for the automotive sector. No longer is it just the vehicle tailpipe emissions being considered, but the entire supply chain. Again, the right fastener partner can help its customers implement more efficient processes to help achieve this.

Better connected

AFL can supply a whole range of automotive fasteners which are particularly relevant for EV and EVB applications

- Fasteners with electrically isolating coatings

- Super lightweight fasteners

- Non magnetic fasteners

- New component fasteners ie Battery retention bolts

- Cable management solutions

- EV charging unit support

AFL exists to connect with its automotive customers as a partner, not just a parts supplier. Our aim is to really understand the problems you are facing, to collaborate with you and to help you solve that problem. AFL supports both automotive OEM and aftermarket customers across a whole range of segments including car, truck, commercial, motorcycle, construction and defence.